Buying downloadable laser cut files has never been easier. Online marketplaces offer thousands of SVGs, PDFs and DXFs that look beautifully detailed on screen. However, once these designs are sent to a laser cutter, many customers quickly discover that the files are not actually ready for cutting in their current state, necessitating laser cut file optimisation to prepare them properly.

At Tekneek Lasering, we work with laser files daily, and the truth is simple: most downloaded laser cut files require optimisation before they can be safely and cleanly cut from materials like MDF, acrylic, aluminium, or stainless steel.

1. Visual Design Doesn’t Equal Functional Design

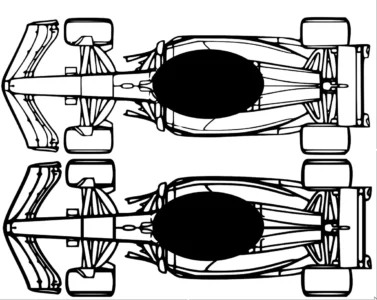

A perfect example is shown in the F1 vector artwork.

- The top version shows the file exactly as downloaded.

- The bottom version shows the corrected version we adjusted to suit 3mm MDF.

The customer wanted to hang the finished piece using two mounting points at the top wheels. However, the original file had extremely thin linework. Once cut, the design would have warped, bent, or snapped, especially across the long unsupported sections.

To make the design laser-ready, we:

- thickened structural lines,

- strengthened weak connection points,

- smoothed irregular curves, and

- simplified areas that were too delicate for MDF.

This level of optimisation is common — and essential.

2. Material Choice Affects the File Requirements

Each material behaves differently under laser heat:

MDF

Fine lines and tiny bridges break easily. Designs often require stronger outlines and simplified linework.

Acrylic

Small letters or thin strokes often warp because of the heat. Files designed for paper or vinyl almost always fail when scaled down for acrylic.

Metals

Also require clean geometry, proper spacing, proper sequencing, tabs and more .

What works for a digital preview or a vinyl plotter is often completely unsuitable for laser cutting.

3. Text and Fonts Almost Always Need Correction

Typography is one of the biggest flaws in downloaded files.

Fonts typically contain:

- distorted curves,

- uneven line transitions,

- excessive nodes,

- wobbly shapes and poor flow.

In the example provided, the top version shows the original font with irregular, jagged curves. The bottom version shows the corrected, smooth and professionally cleaned version — ready for engraving or cutting.

Smooth vector curves are critical for:

- clean engraving,

- accurate cutting,

- reduced burn marks,

- high-quality finishes.

4. Why Laser Cut File Optimisation Matters

Correcting and preparing a file before cutting ensures:

- stronger structural integrity,

- cleaner cut edges,

- reduced warping or snapping,

- better material performance,

- a professional-looking final product.

This is why Tekneek Lasering offers laser cut file optimisation as part of our service. Whether you purchased a file online or designed it yourself, we ensure it is 100% suitable for the material you choose.

5. When to Get Your File Checked

You should consider file optimisation if:

- the design has very thin lines,

- the artwork is cut from MDF or acrylic,

- the design will be hung or supported from only a few points,

- the text looks rough, uneven or distorted,

- the file is downloaded from an online marketplace,

- the artwork is scaled smaller than the designer intended.

A small adjustment now prevents a failed cut, wasted material and extra cost later.

Conclusion

Downloaded laser-cut files are a fantastic starting point — but they are rarely ready for production. Proper laser cut file optimisation ensures your artwork cuts cleanly, stays structurally strong, and looks exactly how you imagined.

If you need help preparing your file for laser cutting, Tekneek Lasering can refine, strengthen and smooth your design so it’s completely cut-ready for MDF, acrylic, metal and more.